CRUSH THOSE CRAVINGS

Your Willpower's New Best Friend!

PROARGI-9+

The highest quality l-arginine supplement in the world.

• Supports overall cardiovascular health

• Enhances blood flow to vital organs

• May aid in decreasing body fat and building muscle mass

• Helps maintain healthy blood pressure levels

WHAT CUSTOMERS

ARE SAYING

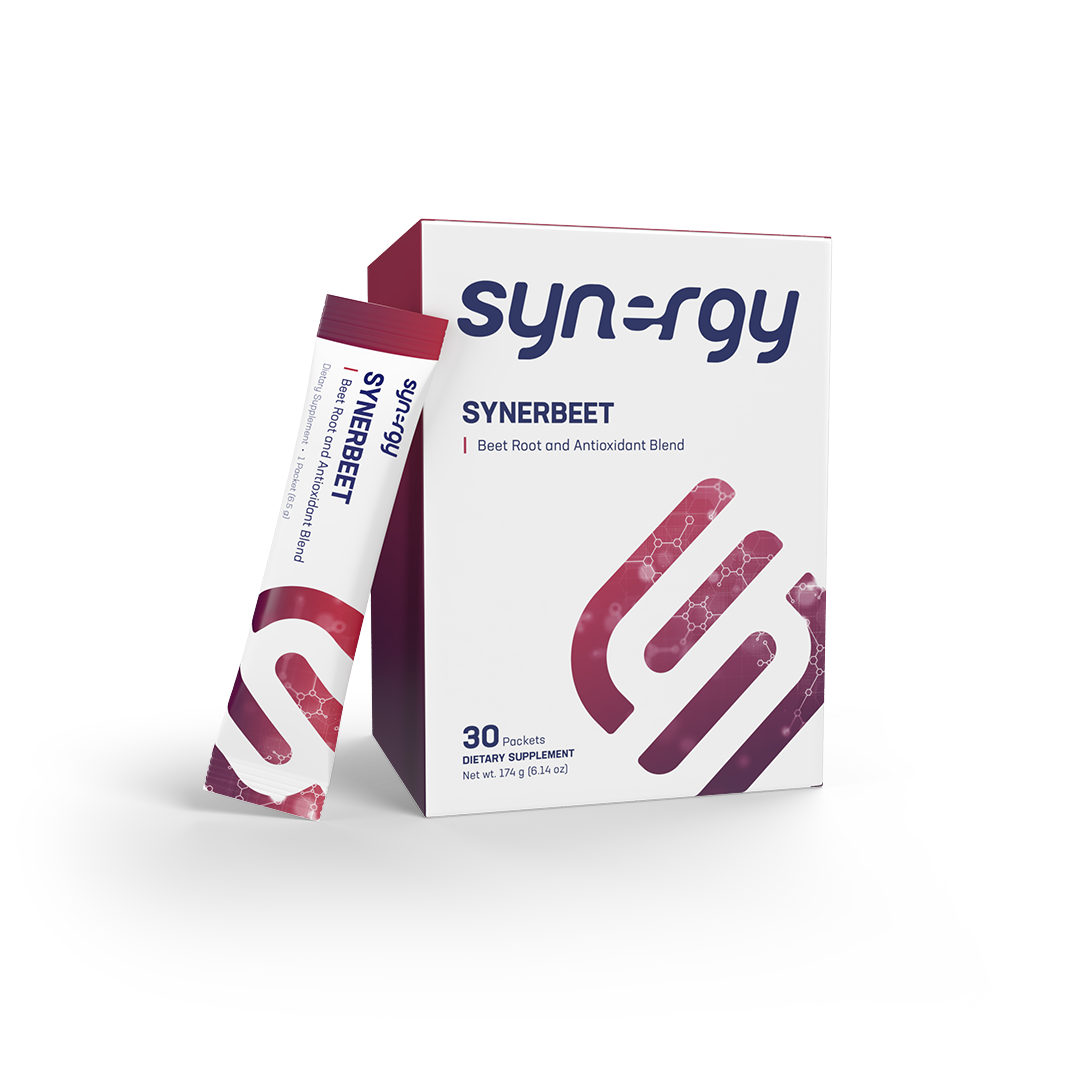

"SynerBeet has been a gamechanger! It gives me that much needed boost for my workouts or tackling all the things on my busy to-do list."

CHELSEA M.

THE NORTH AMERICA SYNERGY TEAM DONATED $25,000 TO THE HEART CENTER AT PRIMARY CHILDREN’S HOSPITAL IN 2023 TO ENSURE THE HIGHEST QUALITY CARE FOR PATIENTS.